Cutting stainless steel is not only for experienced tradespeople. Taking the correct approach will depend on the nature of your project. As a beginner, you can also learn how to use the appropriate tools and techniques to cut stainless steel.

The most common way to cut stainless steel is using a circular saw, jigsaw, angle grinder, or plasma cutter. The specific tool and method will thus depend on the thickness of your stainless steel sheet. Unless it is a thin sheet, shears will do just fine.

You can use a pair of tin snips or power shears to cut thin sheets of stainless steel (26-15 gauge). These tools work like scissors, so it is an easy way to start working through steel if you’re a beginner. However, thicker stainless steel sheets will require different tools and a few additional considerations and steps.

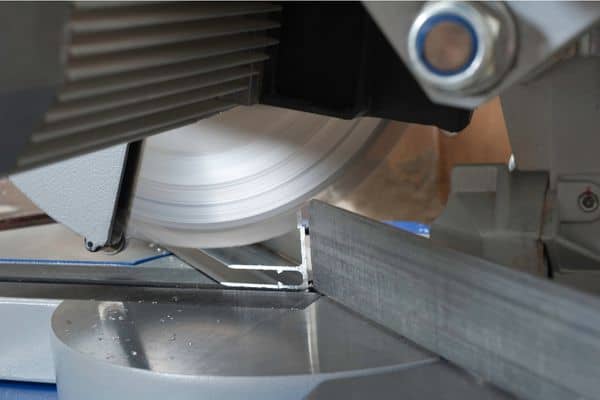

1. Cutting Stainless Steel With A Saw

A circular saw or jigsaw is essential if you want to cut thicker stainless steel sheets and other materials that are too thick for tin snips and power shears.

The technique for cutting stainless steel with a circular saw and a jigsaw is the same unless you want to make an interior cutout, in which case a jigsaw will need a starter hole.

Your safety is paramount. Ensure that you put on safety goggles, heavy-duty gloves, and long pants to protect yourself against metal splinters before cutting your stainless steel.

Step 1: Use a Proper Cutting Blade

The best blade to get for your saw is a diamond blade. Diamond blades are more robust than other saw blades, which will help you cut through stainless steel easier.

Step 2: Prepare The Stainless Steel Sheet

Once you have prepared your saw, clamp your stainless steel sheet face down on your work table. If you do not clamp it down, the steel can shift. With the sheet still positioned face down, mark the cutting line with a steel marker on the back of your stainless steel sheet.

Step 3: Start Cutting With The Saw

When ready, line up the saw blade with the section you want to cut by resting the base of the saw on the steel sheet. Switch the saw on and allow it to reach full RPM.

Once it has reached this level, you can slowly make the first cut, following the line you marked with a bit of pressure. Do not force the saw since this can dull the blade and cause the sheet to overheat.

Step 4: Take Care When Done

Turn off the saw when you have completed your cut but be careful when handling the stainless steel. The edges are often rough and sharp, which you can smooth down with a deburring tool, like a metal file or 80-grit sandpaper.

2. Cutting Stainless Steel With An Angle Grinder

An angle grinder can cut thin and thick stainless steel, including sheets, tiles, and broader stock. Like working with other tools, you should make sure that you are wearing the required safety gear before you start cutting your stainless steel.

Step 1: Prepare Your Grinder

Firstly check that your grinder’s center nut and thread have no severe damage. Then check that your disc is the correct type for the job and that it is not broken or worn down. If it is the first time you are cutting steel with an angle grinder, or yours need replacing, you might have to purchase a disc.

Typically, products will have their suitability for cutting materials marked on them, but to start, look for aluminum oxide cutting wheels and select the appropriate size and shape (either Type 1 or Type 27) for your specific grinder and use.

You can also use an all-purpose metal cutting wheel, which will cut through various metals but might not perform as well.

Step 2: Prepare The Stainless Steel Sheet

Position and clamp your stainless steel sheet topside up at your workstation. With the sheet still facing up, mark the cutting line with a steel marker on the front of your stainless steel sheet. Once secured, ensure that the cut-off piece can fall off freely from the workstation, or it may close onto the cutting disc.

Step 3: Start Cutting the Stainless Steel

Put the grinder on and leave it running for about 5 minutes before you start. Cut so that the grinder wheel cuts down into the steel (face side), ensuring that the burrs left from the cutting action are left on the back of the stainless steel sheet.

Step 4: Clean Up

Once you are done cutting, switch off the angle grinder and exchange the cutting wheel for a flap wheel. Now use it to remove any burrs along the cut edges on the backside of the stainless steel.

3. Cutting Stainless Steel With A Plasma Cutter

A plasma cutter is not a standard tool that most people have lying around the house, but it is helpful if you want to cut various metals, including stainless steel. Granted, if you are cutting relatively thin sheets of steel, you do not need this potent tool. But for thicker, more heavy-duty jobs, it is the perfect cutter.

Always wear a face shield, long-sleeve top and pants, and suitable gloves before you start.

Step 1: Prepare Your Stainless Steel

As with other tools, secure your stainless steel in place. Using a steel marker, make a line in the area where you want to cut the stainless steel.

Step 2: Prepare Your Plasma Cutter

Connect the plasma cutter to a 240V or 415V air compressor and turn on the air, ensuring you have a compressed and clean air supply. Then connect the plasma cutter to the torch.

Set the current to an appropriate level, depending on the thickness of the stainless steel you are about to cut. For example, an 18-20 gauge steel will need a current of around 25 units. Finally, attach the ground clamp to the edge of your stainless steel.

Step 3: Cut The Stainless Steel

When ready, switch on the plasma cutter and bring the torch’s handle closer to the stainless steel surface. Depending on your purpose, start from the edge or pierce a hole in the middle of the steel. Press the trigger and trace the line you made with the marker, keeping a steady hand and moving slowly and deliberately to achieve precision.

Step 4: Finish Up

Usually, a plasma cutter cuts pretty clean, but if you want, you can smooth the edges further with an electric file. When done, you must turn off the plasma cutter when you have made the necessary cuts. Then disconnect the air and ground clamp and roll up your hoses to be stored properly.

Conclusion

For smaller DIY jobs around the house involving stainless steel, it is recommended that you stick to using shears, a saw, or an angle grinder. Using a plasma cutter should ideally be left for when you are more experienced in cutting steel and metals and only if you are taking up heavy-duty jobs that require cutting very thick pieces of material.